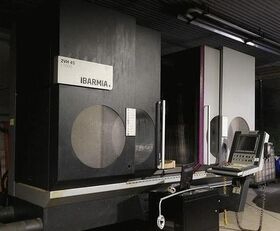

DMG Mori ecoMill 635 V machining centre

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

y-travel 510 mm

z-travel 460 mm

control Heidenhain TNC 620

table surface area 790 x 560 mm

spindle taper: ISO 40

spindle turning speed range 20 - 12000 U/min

Tool changer 30 Pos.

Number of working hours 17162 h

Spindle capacity 13 KW

Feed 20 m/min

rapid traverse 30 m/min

T-slot - distance 100 mm

Table load 600 kg

weight of the machine ca. 3,9 t

dimensions of the machine ca. m

Vertical machining center ecoMill 635 V with slimline panel 3D control

Heidenhain TNC 620, 15" TFT slimline panel with few operating hours; switch-on

hours 17162, SPINDLE HOURS ONLY 1034!

Data transfer: USB, Ethernet, PROGRESSline + Planonlight Display of the

remaining production time and quantity of a complete machining process.

Tool magazine for 30 tools with fast double gripper, cooling device for

main drive. Oil and emulsion mist separator.

Production package 1 consisting of:

Internal coolant lubricant supply 12 bar, tank capacity: 360 l, chip conveyor,

bed flushing cabin roof, flushing gun for chip flushing, coolant-blast air

switching externally via M function, 4-color signal light.

Measure + monitor: Direct position measuring system X, Y, Z including sealing

air for measurement systems, infrared measuring probe made by Heidenhain TS 649

including tool holder.

Machine dealer with own stock of 1600 m².

The data for this ad was created with ModulMWS - the software solution of LogoTech oHG.

y-Weg 510 mm

z-Weg 460 mm

Steuerung Heidenhain TNC 620

Spindelaufnahme: ISO 40

Spindeldrehzahlen 20 - 12000 U/min

Werkzeugwechsler 30 Pos.

Betriebsstunden 17162 h

Spindelleistung 13 KW

Vorschub 20 m/min

Eilgang 30 m/min

T-Nuten - Abstand 100 mm

Tischbelastung 600 kg

Maschinengewicht ca. 3,9 t

Raumbedarf ca. m